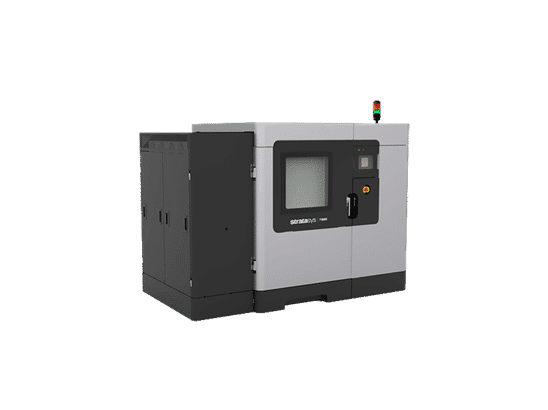

Leading manufacturing brands from every industry across the globe trust Stratasys’ F900 for its consistent uptime, dependable output, and data security. Along with our industry 4.0 game-changing software solutions, F900 is truly unmatched when it comes to industrial-grade 3D printing.

Globally trusted and proven performance.

Our F900 industrial large build volume 3D printer is trusted by industry leaders and government agencies across the globe. This trust has been built throughout years of proven reliability, repeatable, and performance. An absolute requirement in any industrial manufacturing operation.

Versatile portfolio of material options.

The Stratasys F900 offers one of the most diverse portfolios of FDM thermoplastic materials, specifically designed to meet a wide variety of industrial focused applications. From standard ABS to carbon fiber to ESD-capable PEKK, the F900 has various material options to meet any manufacturing demand.

Connectivity and data security.

MTConnect provides factory floor connectivity and ProtectAM safeguards sensitive printer and system data, which enables information processing security, including U.S. DOD STIG compliance, enabled by Red Hat Enterprise Linux software.

| Build Envelope | 914.4 x 609.6 x 914.4 mm Platen supports two build zones for either a small or large build sheet |

| Material Delivery | 2 model canisters & 2 support material canisters of 1508 cc each. Auto changeover between canisters. |

| Material Options | ASA, ABS-M30™, ABS-M30i™, ABS-ESD7™, PC-ABS, PC-ISO™, PC, ULTEM™ 9085, ULTEM 1010, PPSF, FDM Nylon 12™, FDM Nylon 6™, ST-130™, FDM Nylon 12CF™ |

| Layer Thickness | 0.508 mm, 0.330 mm, 0.254 mm, 0.178 mm, 0.127 mm |

| System Size and Weight | 2772 x 1683 x 2027 mm, 2869 kg with Manufacturing Light Tower: 2772 x 1683 x 2281 mm |

| Achievable Accuracy | Within an accuracy of +/- .089 mm or +/- .0015 mm per mm whichever is greater. |

| Network Communication | 10/100 base T connection. Ethernet protocol. |

| Operator Attendance | Limited attendance for job start and stop required. |

| Operating Environment | Maximum temperature 29 °C. Maximum humidity 80%. |

| Power Requirements | 230 VAC (3 phase), 50/60Hz, Voltage fluctuation +/- Current 40A |

| Additional Requirements | Compressed Air Required 90-120 psi with a minimum flow of 20 CFM |

| Regulatory Compliance | CE, cTUVus, RCM, EAC, FCC Part B |

| Software | Insight™, Control Center™, GrabCAD Print™, GrabCAD Print Pro™ |

| Operating System | Microsoft Windows 8.1, 8 (Pro, Enterprise), 7 (Pro, Enterprise, Ultimate), and Vista (Business, Enterprise, Ultimate), Microsoft Windows Server 2008 and 2003 |