CNC machining is a common fabrication method long thought to be a staple of traditional industrial manufacturers across the globe. These machines are accurate and precise and machine metal using “subtractive” methods: they create parts by removing material, rather than adding to it.

But what if you could get better, faster results using an “additive” method instead of a subtractive method? Why not a 3D printer to fabricate using additive technology? Is this economical and feasible?

There is cause for debate as to which is the more suitable method of tooling fabrication: CNC milling, lathes, etc., or 3D printing via additive manufacturing. There are three notable advantages to using additive manufacturing or 3D printing when manufacturing parts, tools, and forms.

When Specifications and Designs Call for Customized Parts and Tooling

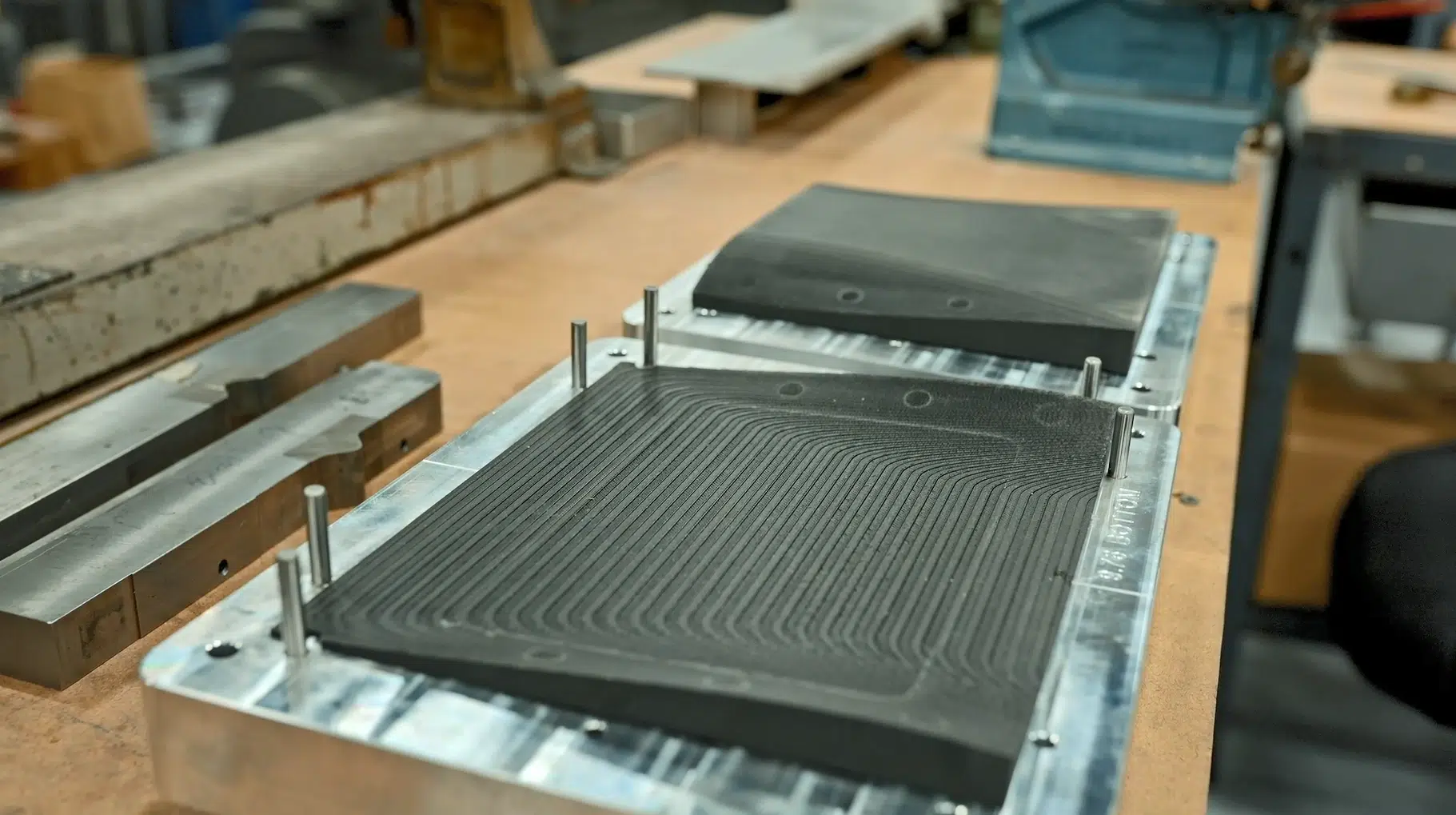

Additive manufacturing expedites the fabrication of customized tools, – creating them faster and cheaper. For example, additive manufacturing has been used to create custom metal forming dies and press brake tools instead of traditional methods. Traditional methods create parts that are machined from tool steels such as A2, D2, or 4140. The tooling is available commercially off-the-shelf (COTS) from several manufacturers in standard geometries. However, this option is not ideal when a custom tool is needed.

The need for a custom tool is often discovered during the design process after fit and function testing. It is often unplanned. Thus, it requires specific material that may have a long lead time and is not readily available. This disrupts the design process, resulting in added costs.

If a custom tool is needed, the cost and lead time to produce it is more favorable with additive manufacturing.

Additive manufacturing, using a fused deposition modeling (FDM) 3D printer is quite capable of making the custom metal forming die, vice CNC machining. It is a better option for volumes ranging from 100-500 cycles. In addition, FDM is also well suited for offset and flare tooling in thinner gauges of sheet metal. It can be produced faster with less waste. Additive manufacturing of the tool saves time and cost over traditional machining methods.

When the Design and Specification of the Fabricated Part is Complex

As with the custom die or brake tool, parts are often complex and require more sophisticated geometries.

Additive manufacturing is ideal for complex parts. It allows multiple iterations of the fabricated part using different designs and complex geometries. Forms may be printed with a specific amount of material, follow complex patterns, optimally utilize available material, and produce such parts faster with less waste. CNC machining usually requires longer lead time material, generates more waste, and is not nearly as fast as 3D printing.

By using additive manufacturing and the right printer, complex geometries may be achieved at moderate production volume, with much less time and effort.

For example, Stratasys FDM technology can print several high-strength thermoplastics that can withstand the pressure of forming thin-gauge metal. This allows a production tool to be manufactured from additive processes. What’s more, the volume of the tool need not be small in volume.

When Part Labels are Required

One significant advantage of producing parts with additive manufacturing or 3D printing is the possibility of printing specific part labels on the part, using the 3D printer.

Maintaining and tracking parts inventory is crucial nowadays. Parts may be barcoded or labeled with key information that allows their inventories to be finely controlled. Labeling parts, however, sometimes requires a separate process whereby a label must be printed or affixed to a part. Such a process is an adjunct, but usually separate from the part’s fabrication.

With the detailed capabilities of 3D printing, a part may be labeled with a barcode and other specific information by printing it on the part, as part of the fabrication process. This may even be more sophisticated as part labels may be printed such that they do not show up at all, and are somewhat indelible, but can be scanned or identified by using say an infrared reader. This is an important benefit of additive manufacturing in lieu of CNC machining or other metal forming processes.

There’s certainly merit in both CNC and additive manufacturing. CNC machining has been and will continue to be, a viable means of fabricating parts. 3D printing brings advantages that are difficult to match with traditional manufacturing technologies. The cost to fabricate and the time needed to produce parts are minimized using 3D printing.

The final decision rests with the product life cycle team and their objectives. Let us help you decide.

Email: [email protected]

ARTICLE WRITTEN BY STRATASYS